Traditional supply chains often need more flexibility and efficiency. These constraints can hinder a business’s ability to adapt to market changes and operational demands, leading to significant drawbacks. According to a McKinsey study, the average supply chain has a digitization level of 43 percent. Understanding these challenges is crucial for businesses seeking to optimize their logistics operations.

In traditional supply chain models, the reliance on single-mode transportation solutions often results in a need for more flexibility. Businesses find adapting to changing market conditions challenging, making them highly susceptible to disruptions. Limited options for transportation modes restrict the ability to switch quickly and efficiently, exacerbating the issue when unexpected events occur. This rigidity can lead to delays and inefficiencies, ultimately affecting customer satisfaction and business performance.

Inefficiencies are another critical challenge in traditional supply chains. Suboptimal route planning can lead to increased transit times and higher operational costs. The inability to integrate various transportation modes often results in fragmented logistics operations, further inflating costs and reducing overall logistics performance.

For example, a company relying solely on trucking may face delays due to road congestion, whereas integrating rail or air transport could have mitigated such delays and improved delivery times. These inefficiencies affect the bottom line and customer satisfaction due to delayed shipments and unreliable service.

An unimodal supply chain strategy integrates multiple transportation modes into a seamless and adaptable logistics solution. This approach enhances flexibility and efficiency, addressing the challenges identified in traditional models.

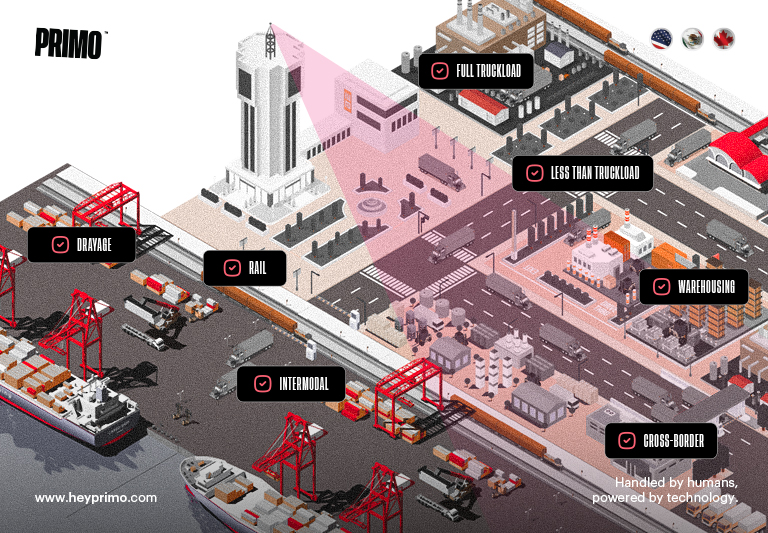

Incorporating various transportation modes such as dry van, reefer, flatbed, heavy haul, and bulk into a single cohesive strategy offers multiple benefits. Businesses gain the flexibility to choose the most suitable mode for each shipment, ensuring that diverse shipping requirements are met efficiently. For instance, perishable goods can be transported via reefer trucks, while oversized cargo can be handled using flatbeds.

This multimodal approach, albeit far more similar to a true omnimodal offering, improves logistics performance by optimizing different transportation options, leading to better resource allocation and cost savings. Companies can leverage the strengths of each mode to enhance overall logistics efficiency.

An omnimodal approach allows businesses to adapt to changing market conditions and customer demands. Switching modes seamlessly allows for real-time adjustments based on demand fluctuations. For example, during peak seasons, businesses can shift from road to air transport to meet expedited delivery requirements. Enhanced visibility across the supply chain, achieved through advanced TMS and other technology solutions, ensures that businesses can respond swiftly to any changes, maintaining operational efficiency and flexibility. This adaptability is crucial for managing unexpected disruptions and ensuring timely deliveries.

An evolving and omnimodal strategy allows seamless switching between transportation modes to meet dynamic requirements. This adaptability is crucial for handling various shipment sizes and types, ensuring that logistics operations remain efficient and flexible. Shippers can optimize transportation strategies based on specific needs, such as expedited shipping or cost reduction. Real-time mode adjustments optimize logistics performance, providing customizable solutions for different industries. This flexibility helps businesses stay competitive and responsive to market demands.

For example, combining sea and rail transport can significantly lower costs compared to air freight. Efficient resource allocation and load management further contribute to cost savings, making international shipping more cost-effective.

A new approach to logistics management is always clean, cut and dried. Instead, it’s filled with opportunities and ways to do more with less. In the supply chain, this means knowing how to make the best decision based on all available information, and in an omnimodal context, this can be boiled down to taking six core steps, including:\

Omnimodal is still relatively new in logistics, and its value grows as disruptions become more rampant. The evidence is clear. An omnimodal supply chain strategy can revolutionize logistics operations by providing flexibility, cost-efficiency, and reliable customer support. Connect with a PRIMO team member today and start optimizing your supply chain.